| Essential

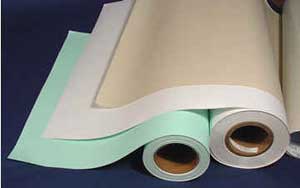

glass etching materials! Our etching resists are made especially for etching on glass, they are not recycled from other industries. They are thick enough and tough enough to repel the blasting abrasive , but the adhesive releases cleanly from the glass after the etching is finished. There are different thicknesses, and they come on rolls of different widths and lengths. They all have at least a year long shelf life. In selecting the right resist for the job, you will obviously need to know a little about etching, but we will try to explain the basics here. All this information and much more about resists is found in our books, videos and hands-on seminars. |

|

|

|

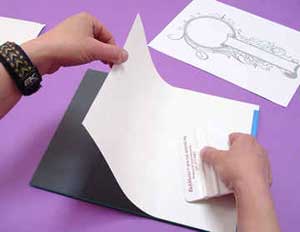

Apply the resist to the glass (or the back of the mirror in this example) using a wide, flat plastic squeegee. This insures that the resit goes down without trapping bubbles (creating weak spots that might blast through, when using thinner resists). The plastic will not damage the resist while applying it. Be sure to visit our page on squeegees and knives to get the best of both! |

| Basics of etching resists For blasting at higher pressure (eg. multi-stage carving, deep single stage carving, or surface etching large areas with coarse abrasive), most glass etchers prefer to use thicker resist. For light surface etching in medium to small areas or for shading, use thinner resist. You can always use a thick resist for a blasting job that normally doesn't require one. You will pay more for it, but it does give an extra margin of safety. |

|

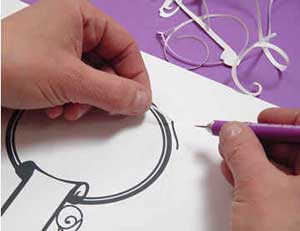

After cutting each element with a stencil knife, remove the elements of the resist where you want the etch to appear on the glass. For this process, you can use your stencil knife, but the point can easily break, which can get costly if it happens often. It is better to use a picking needle or "weeding" needle, shown above. You can get these from our page on squeegees and knives. |

You can use these resists on round objects like glassware, too. |

| However, you may be asking for trouble if you try to use a thin resist where a thick one would normally be used. In this case, you will save a little money, but if your pressure is too high, your abrasive particles too large, or if you hold your nozzle too close, you may go through the resist and ruin the glass you are etching. Depending on the cost of the glass, the effect of this could vary from a mild annoyance to disaster. Different resists have different cutting characteristics with stencil knives. Rubber and soft vinyl resists are much easier to cut than regular vinyl resists, but are always thicker and more expensive. (Because of the ease of cutting the softer resists, many people prefer using them for all their etching in spite of the extra cost.) We have listed a table below with the different thicknesses of resists, our suggestions about their recommended uses, the roll sizes they are available in and their prices. The recommended uses are suggestions only, and are subject to your own experience and preferences. For example, it is possible to carve glass deeply using the thinnest of resist. HOWEVER - you really have to know what you are doing. You have to slow your etching speed down, keep the pressure low, keep your hand moving, etc. so you don't over heat the resist. This process will also take much longer than with thicker resist. |

|

| Type of resist

|

Characteristics

|

Recommended Uses*

|

| 8 mil thick x 18" wide x 10 yards long | White vinyl, (hard vinyl) | This is your standard opaque blasting resist. It's 50% thicker and safer than 4 mil, but only costs 10% more. Good for surface etching, multi-stage shading, slight depth carving to 1/16" or less. |

| 8 mil thick x 18" wide x 50 yards long | White vinyl, (hard vinyl) | |

| 8 mil thick x 24" wide x 10 yards long | White vinyl, (hard vinyl) | |

| 8 mil thick x 24" wide x 50 yards long | White vinyl, (hard vinyl) | |

| 8 mil thick x 30" wide x 10 yards long | White vinyl, (hard vinyl) | |

| 8 mil thick x 30" wide x 50 yards long | White vinyl, (hard vinyl) | |

| 8 mil thick x 18" wide x 10 yards long | Clear vinyl | This is your standard clear blasting resist. Good when you need to see through the resist to correct mistakes in previously etched designs, for use when you need to trace the pattern through from underneath, or when you just need to protect the back of a piece you are working on. Difficult to use for shading and only tough enough for carving up to 1/16" deep or less, so used primarily for surface etching. |

| 8 mil thick x 18" wide x 50 yards long | Clear vinyl | |

| 11 mil thick x 25" wide x 20 yards long | Soft vinyl | Very soft and easy to cut. Great for wrapping around curved or 3D objects. Good for multi-stage shading, surface etching, and excellent for light to medium depth carving (between 1/16" and 1/8" deep). Tends to suffer from shrinkage after being cut, so cut lines will open up a bit if you wait several days after cutting before you etch. |

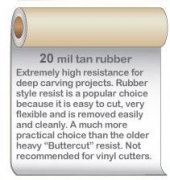

| 20 mil thick x 25" wide x 10 yards long | Rubber | Hand cut only. Very soft and easy to cut. Great for wrapping around curved or 3D objects. Excellent for medium depth carving (over 1/8" deep). Can also be used on stone. |

| 25 mil thick x 25" wide x 10 yards long | Soft vinyl | Soft and easy to cut. Excellent for medium to very deep glass carving (1/4" deep or more). Very good for stone or wood. Tends to suffer from shrinkage (see 11 mil above). |

| * Remember, the carving depths mentioned here are only guidelines, to be checked against your own experience. Your success depends on how much experience you have and how you set up your blaster. If you have problems, please refer to our books and videos. As mentioned above, you can carve with resist as thin as 4 mil (which we don't carry) or surface etch with resist 25 mils thick, depending on conditions. |

||

| ** For more information and to purchase an item, click on the code link for that product. To add one of an item to your shopping basket right away,

click on the "Add One to Basket" button. After clicking the button, you will be brought back to this page. To view the items in your basket at any time, click on the "Basket Contents" button at the top of every page. |

||