My Cart: 0 item(s)

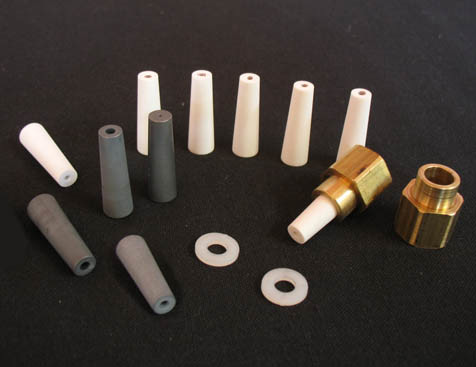

A Sandblasting Nozzle constricts the high pressure stream of abrasive at the end of the hose and directs it at the project. The abrasive rushing through the nozzle enlarges the hole, and eventually, it must be replaced. As the hole enlarges, the system requires more air. Eventually the orifice is so large that the compressor runs constantly and is unable to maintain the proper pressure.

Advantages of Ceramic Nozzles

- Ceramic nozzles are very inexpensive compared to carbide nozzles

- Because they are less expensive, it is easier to own a wider variety of sizes

- Ceramic nozzles are perfect for the infrequent blasting artist

- Carbide nozzles last 10 times longer than ceramic nozzles

- Saves time when blasting: not having to stop and replace nozzles

- Carbide nozzles are great for the 'non-stop' blasting artist